The use of photovoltaic combiner box.

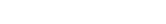

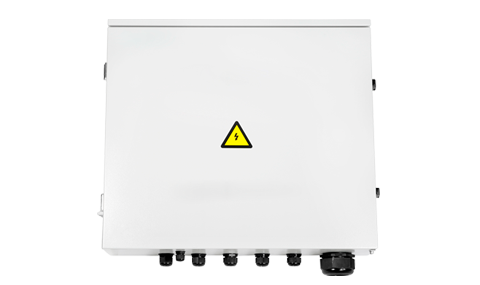

The intelligent solar power combiner box is an intelligent product used in photovoltaic power plants to monitor the photovoltaic tube series and external auxiliary components. Because the effectiveness of solar rechargeable batteries is very low, in order to produce a solar grid connected power plant with a certain capacity, a large number of solar panels must be connected in series and parallel to generate the required power. During the entire process of connecting solar panels in series and parallel, in order to reduce the wiring connection between the rechargeable batteries and the inverter, reduce the complexity of the system, and improve stability, several rechargeable battery series are generally selected and connected to the solar power generation combiner box in the nearest direction for primary convergence, and then several combiner boxes are connected to the inverter side for secondary convergence.

In the solar power generation system, in order to effectively reduce the connection between the solar cell array and the inverter, it is applied to the combiner box. A solar power station using a small inverter does not require the use of a combiner box because the small inverter is paired with each rechargeable battery. Off grid means that you have not connected to the power supply system or public utility enterprise of the * * grid in any other way. This is very tempting because you maintain your own calorie expenditure.

In order to reduce the total number of cables on the DC side, provide high efficiency, convenient maintenance, and improve stability for the power plant system software, it is generally necessary to install DC combiner equipment (combiner box and DC distribution box) between the photovoltaic modules and inverters for large and medium-sized photovoltaic grid connected power plant system software. The combiner box performs primary combiner and the DC distribution box performs secondary combiner.

The software of the solar power station system consists of components (solar lithium battery modules, commonly referred to as components in the text), inverters, combiner boxes, distribution cabinets, support frames, and connecting transmission lines. Any difficulty that occurs at any stage can jeopardize the operation of the power plant, ranging from damaging the kinetic energy of the generated electricity to causing significant losses due to fire accidents. According to the statistics and analysis of the editor, the common faults of DC side machinery and equipment such as components, inverters, and combiner boxes in the abnormal solar power plant system account for up to 90.18%, while the common faults of communication AC side machinery and equipment such as cables, transformers, civil engineering, and booster stations account for 9.82%.

The core content of a solar powered road power plant is the photovoltaic system software, which utilizes the photoelectric ampere effect of solar rechargeable cells to immediately convert solar radiation into electromagnetic energy. Generally, a certain number of photovoltaic module strings are used to converge multiple strings according to the DC combiner box. After being transformed by an inverter and a protective transformer into a voltage that meets the frequency and working voltage requirements of the power grid, it is connected to the power grid.

Customers can connect a certain number of photovoltaic modules of the same size in series to form one photovoltaic module series based on the DC working voltage range input by the inverter, and then connect multiple series to the solar power lightning protection combiner box for convergence. The output is based on the power lightning arrester and isolation switch, which facilitates the connection of subsequent inverters.

The current of the components continues to increase, and at the same time, the output power of the inverter or the total number of strings matched with the combiner box also continues to increase. In the future, the output power of the DC side of solar power generation will further expand, resulting in increased security risks for the entire power plant system software of the components, cables, and inverters.

In solar power plants, DC cables generally refer to the cables between the photovoltaic modules and the inverters of the solar power generation array, and the scope involved is equivalent to that of the solar power generation array. The DC cables in a solar power generation array generally include three sections: photovoltaic string DC cables, solar power generation array DC cables, and solar power generation array DC cables. After several photovoltaic groups are connected in series and parallel, a convergence is carried out at the photovoltaic group string convergence box. In a convergence scenario, it is very likely that the DC cables of the solar power generation array and the solar power generation array are not involved; After the DC cables of the solar power generation array output from several sets of combiner boxes are connected in series, secondary combiner is carried out at the combiner box of the solar power generation array. In the scenario of secondary combiner, it is likely that the DC cables of the solar power generation array are not involved.