-

New Energy

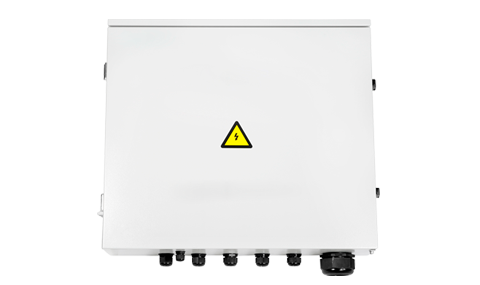

Mobile Energy Storage Energy Storage Cabinet Stacked Energy Storage PEDF Energy Gateway EMS Photovoltaic Equipment

-

Power

Low voltage switchgear High voltage switchgear Three boxes and supporting Box type transformer

-

Solution

Photovoltaic storage charging Commercial complex Manufacturing Smart Farm

- News

-

Service

Product Brochure User Manual Promotion Video Operation Tutorial FAQs

- About Us